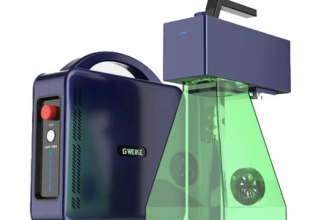

Create lightweight laser cut earrings from wood or acrylic — ready-to-sell SVG templates ranging from layered dangles and hoops to monogram studs. They work on CO₂ and diode machines (Glowforge, xTool, OMTech).

Additionally, these precision-cut designs balance style and craftsmanship. Whether you prefer bold statement pieces or subtle geometric shapes, your earrings will feel modern, durable, and market-ready.

Laser Cut Earrings: SVGs, Materials & Quick Setup

Pick ready-to-cut files and a short starter kit, then begin producing earrings on compact lasers (xTool / Glowforge / diode). For cleaner cuts, mask with transfer tape; moreover, enable Air Assist and keep optics clean.

This post contains affiliate links. As an Amazon Associate, we may earn from qualifying purchases.

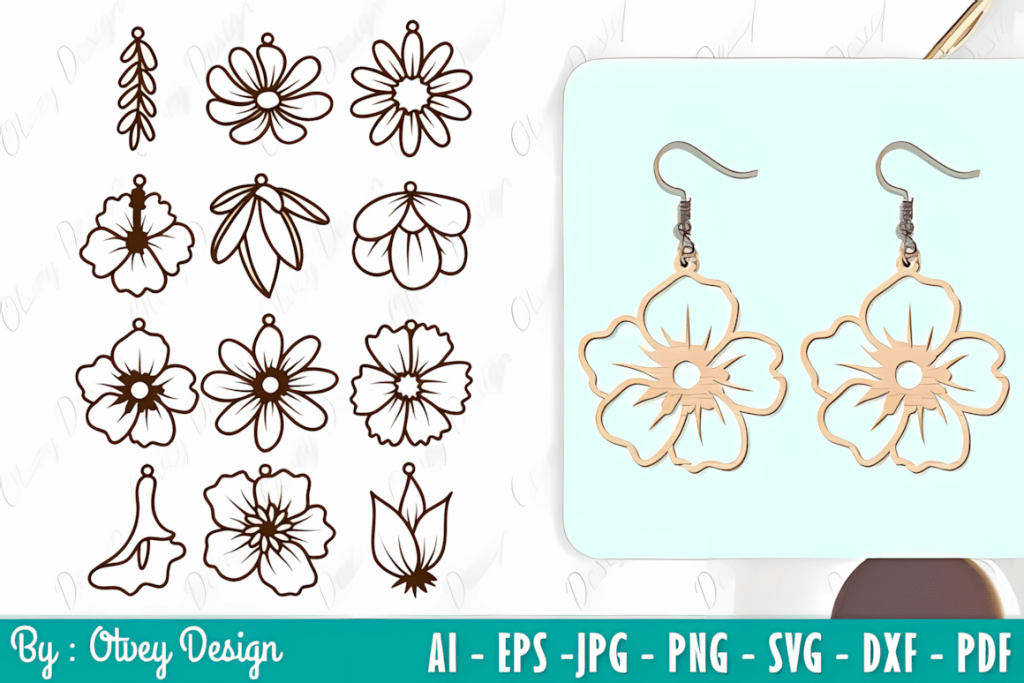

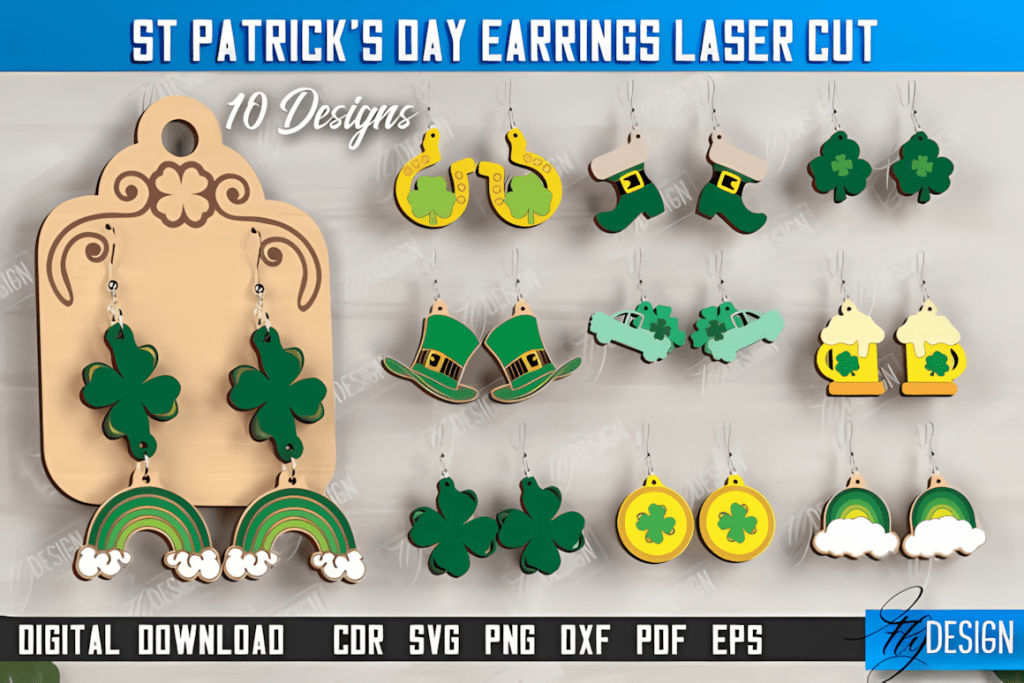

Types of Laser Cut Earrings

Layered (Wood/Acrylic)

3D stacks, inlays, lightweight MDF/basswood.

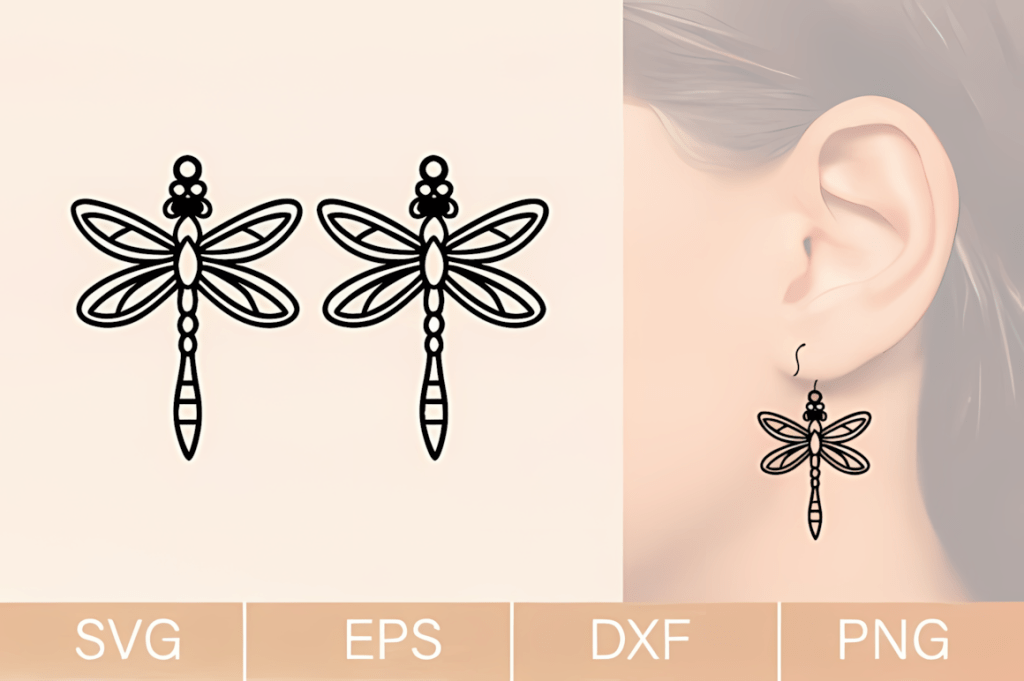

Dangles

Geometric, boho, statement shapes.

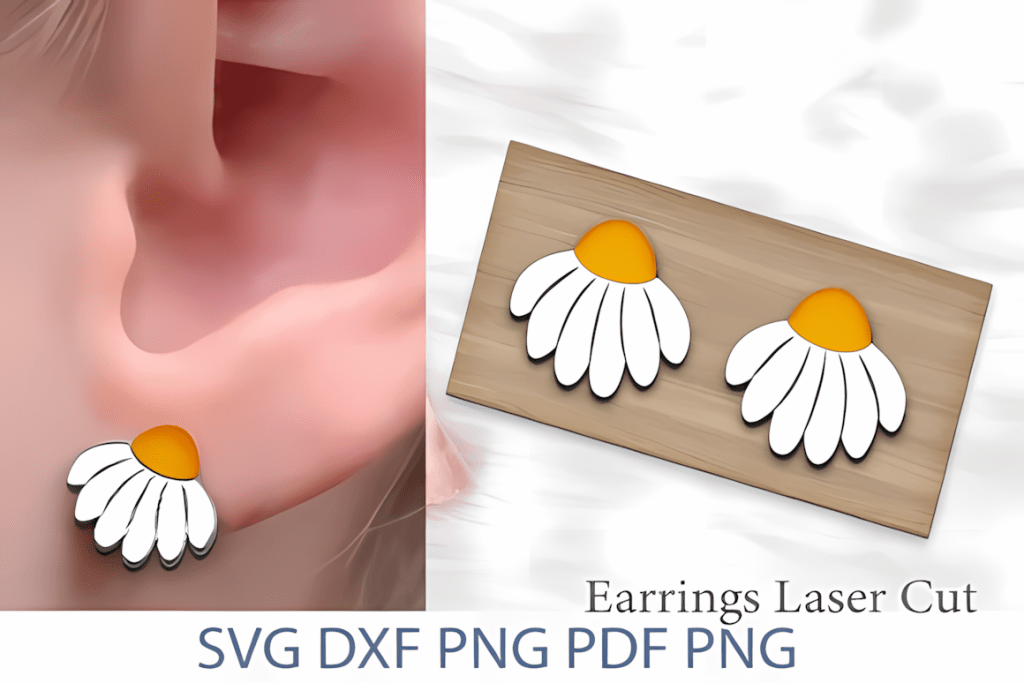

Studs

Mini circles, hearts, seasonal sets.

Acrylic

Cast acrylic, mirrored/fluorescent, frosty engraves.

Monograms & Initials

Letter frames, personalized gifts.

Leather / Faux Leather

Ultra-light dangles; perfect for diode lasers.

How to Make Laser Cut Earrings

- 1Material: 1/16–1/8″ basswood or 3 mm cast acrylic. Mask wood with paper transfer tape.

- 2Run a LightBurn test grid. Cut/engrave (Air Assist on). Clean edges.

- 3Hardware: 6 mm jump rings, fish-hook ear wires (nickel-free). Assemble with flat/needle-nose pliers.

- 4Finish: seal wood (clear coat) or polish acrylic; add backs for studs; card and package.

Why Choose Laser-Crafted Jewelry?

Laser-etched or laser-crafted earrings provide a level of detail that traditional methods often can’t achieve. This technology allows for incredibly precise cuts, resulting in lightweight yet durable pieces that reflect your unique style.

Earring Hardware & Tools

LightBurn Test Grid — Free Download

Download the ZIP, unzip it, then in LightBurn go to File → Import and pick a grid. Run it on your material to find the best Speed/Power.

Popular Materials and Styles

- Wood: Natural grains and textures give wooden earrings a warm, rustic charm.

- Acrylic: Vibrant colors and glossy finishes add a contemporary twist to any outfit.

- Metal: Sleek metal designs, such as stainless steel or brass, cater to minimalist or industrial aesthetics.

- Layered Designs: Combine multiple materials or colored layers to create eye-catching 3D effects.

Need a custom laser-ready file?

Get an SVG tailor-made for your machine and material — fast turnaround, commercial use ok.

Tip: share size (mm), material (plywood 3 mm / acrylic 2 mm), and kerf for best results.

Where to Find Designs

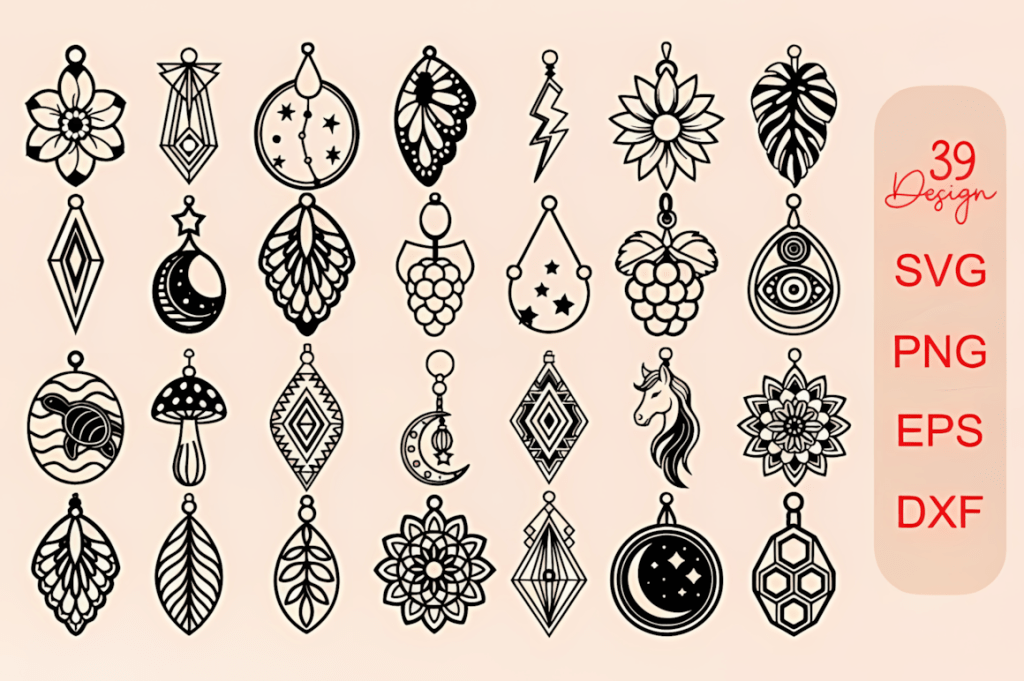

Looking for templates or inspiration? Check out our Laser Cut Files page, where you’ll discover a range of ready-to-use patterns suitable for earrings. For even more options, head over to Creative Fabrica, a platform offering extensive design resources—from simple shapes to elaborate motifs.

Creative Fabrica — Best Laser SVG Files

Most-loved bundles for quick gifts and small business sales.

Tip: CF runs frequent promos (e.g., “first 10 downloads free”). Grab them while they’re live.

Tips for Creating Your Own Laser-Etched Earrings

- Select the Right Material: Choose a material that suits your style and comfort level, especially if you have sensitive ears.

- Mind the Thickness: Make sure your chosen sheet material is thick enough for durability but not so thick that it becomes heavy.

- Test Before Production: If you’re using a laser-cutting service, start with a small test batch to ensure the final product matches your vision.

- Personalize It: Add custom engravings, monograms, or inlays for a truly one-of-a-kind look.

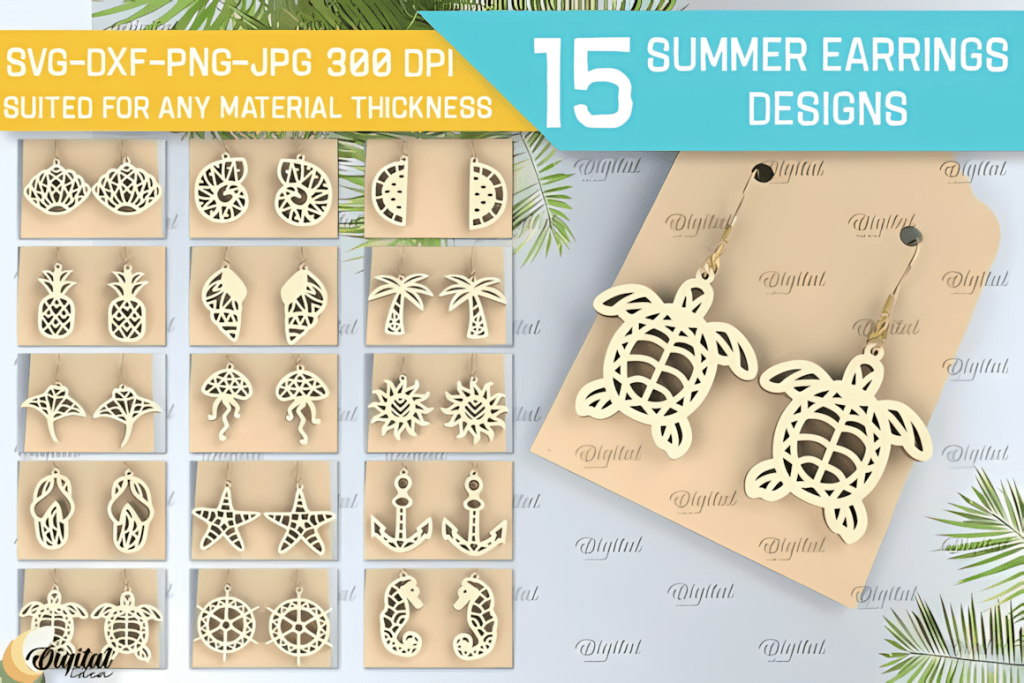

Summer Earrings Laser Cut SVG Collection

Laser Starter Kit

A mini kit for your first 10–15 projects: safety, fixtures, measuring.

Tools

Materials

Make a Fashion Statement with Precision

From geometric patterns to nature-inspired silhouettes, laser-crafted earrings let you express your individuality. Embrace modern technology and timeless design principles to create pieces that stand out, whether you’re dressing up for a night out or accessorizing for everyday wear.

Browse by Category

FAQ

What thickness of plywood/basswood should I start with?

For diode/CO₂ start with 1/16–1/8″ (1.5–3 mm) basswood/balsa; laser-grade plywood 2–3 mm is a great “clean-cut” thickness.

How do I avoid scorch marks and yellowing?

Mask the surface with transfer paper, turn on Air Assist, and increase speed when you have enough power to maintain the cut.

What’s a quick way to dial in settings?

Run a test grid (power/speed + focus step) and keep a printed “quick card” for each common material & thickness.

Can a diode laser engrave acrylic?

Clear/white acrylic engraves poorly (diodes ≈450 nm). Black/colored cast acrylic engraves much better; or use a paint-mask trick.

What glue should I use for layers and bases?

CA glue + activator for small parts; PVA/contact cement for large flats. For acrylic: acrylic cement (Weld-On 3/4) or CA gel.

Is PVC or vinyl safe to laser cut?

No. Avoid PVC and chlorinated vinyls — they can release corrosive and harmful gases and damage your machine. Use laser-safe materials like cast acrylic, laser-grade plywood, paper/card.

Cast vs extruded acrylic — which should I use?

Cast acrylic cuts cleaner and engraves to a frosty finish. Extruded tends to melt more and gives less contrast.

What is kerf and how do I get tight-fitting joints?

Kerf is the width removed by the beam. Measure it on your exact material (typical ~0.05–0.20 mm) and apply a kerf offset or adjust slot widths.

Best material thickness for laser cut earrings?

Wood: 1/16–1/8″ (1.5–3 mm) basswood/plywood. Acrylic: 2–3 mm cast acrylic. For large dangles keep weight down with cutouts; for studs 2 mm works great.

What earring findings are skin-safe (nickel-free)?

Choose 316L surgical steel, titanium (Grade 1/2), or niobium. Gold-filled/sterling are good options too. Avoid unknown “nickel alloy” hooks.

What hole size should I design for jump rings?

For 6 mm jump rings in 20–21 ga (≈0.8–0.9 mm wire), use a hole 1.8–2.0 mm. For thicker 18 ga (~1.0 mm), use ≈2.2 mm. Add 0.1–0.2 mm for kerf and keep at least 2 mm from hole edge to part edge.

Do I need to seal wood earrings?

Yes, for durability & odor control. Lightly sand (320→600 grit) and seal with clear acrylic spray, polyurethane or shellac (both sides). Let cure fully before assembling.

How do I polish acrylic edges on earrings?

Use cast acrylic. Deburr lightly, then wet-sand (600→1000 grit) and finish with plastic polish (e.g., Novus #1/#2). Flame polish only on cast acrylic and with care.